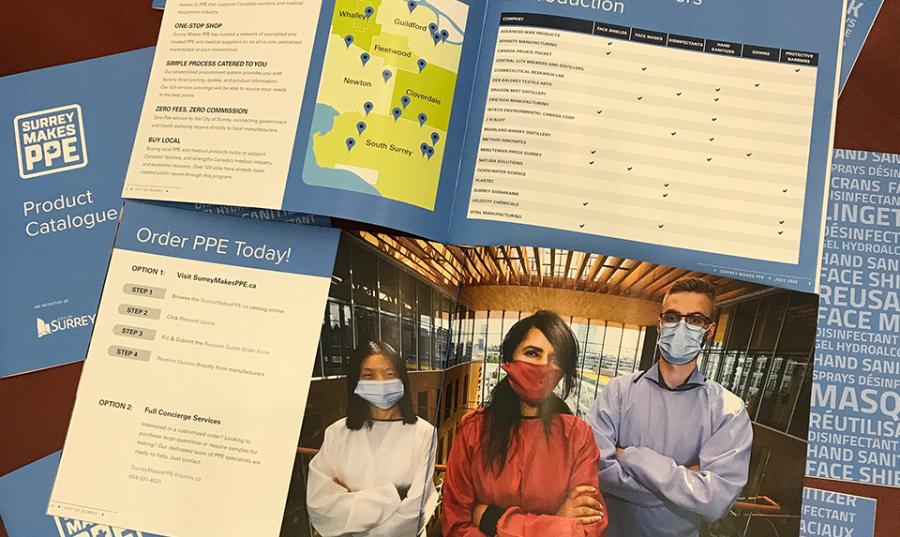

Surrey Makes PPE manufacturers are ramping up production of locally-made personal protective equipment (PPE) as we enter the second week of Phase 2 in BC’s Restart Plan. 25 manufacturers have joined the initiative, with 13 currently producing PPE including face shields, masks, barriers, and hand sanitizers. Among these is METHOD Innovation Partners Inc., who has pivoted their engineering and manufacturing expertise to produce face shields that currently adapt to a variety of non-medical industry requirements. They are currently in the process of getting a number of the shield models approved by Health Canada and the CSA.

“We’re seeing an evolution in the standard face shield. Companies are coming to us and requesting additional features, such as 90 degree swiveling or ability to attach and detach from hard hats and bump caps. Some have ordered face shields from abroad that have deteriorated over the course of a few weeks and they are looking for more reliable options. We are partnering with multiple vendors and clients to adapt the shields for different industry requirements. With five different models, we are already positioned ot offer a shield option for nearly every industry,” explains Dan Wetzel, Marketing Manager of METHOD Innovation Partners Inc. “What really sets us apart is that we have a team of highly qualified industrial designers that are able to take these requirements and very quickly come up with a solution.”

METHOD Innovation Partners Inc’s PPE manufacturing process started in March when they were approached to help with the development of face shields for frontline workers. Since then, their in-house design team has undergone several iterations of design improvements to increase functionality and durability. The resulting face shields are not only able to save lives, but also help to reduce much of the waste issues created by single-use PPE. These shields have been seeing increased demand with over 50,000 units requested from front line essential workers, food processing plants, teachers, dentists, food service, construction workers and personal service establishments across Canada and the United States.

As demand has been increasing for their products and services, the company is in the midst of moving forward with its expansion plans into Surrey’s Campbell Heights and is expected to move production there in June 2020. The larger 32,000 sq ft space will accommodate their in-house design team and manufacturing operations, as well as provide room for employee growth and addition of new machines.

The City of Surrey has been very supportive with the Surrey Makes PPE program and we’re excited to continue working with them to support the fight against COVID-19. We are all-in in helping the city, the province and the country restart our economy in a safe manner.

-Dan Wetzel, Marketing Manager

Visit the Surrey Makes PPE marketplace to discover our expanding list of locally-manufactured PPE.